The Evolution and Future of Diecasting in Malaysia

BusinessDiecasting is a major industry in Malaysia has increased significantly in the past decade and has become important element of the nation’s manufacturing industry. Diecasting is a procedure that involves putting molten metal into molds at extreme pressure in order to create robust, complex parts. The process is used extensively in various fields, such as electronic, automotive and consumer products, in which precision as well as strength are vital. The strategic position of Malaysia within Southeast Asia, coupled with the well-constructed infrastructure and highly well-trained workforce has established Malaysia as a center of high-end diecasting solutions which has attracted global brands to the shores of Malaysia.

One of the main reasons for Malaysia’s diecasting business is the expanding automotive industry. Malaysia is an important producer of parts for automobiles, and diecasting is a crucial element in the production of lightweight and durable parts like engine blocks, transmission case as well as structural components. In the future, as the automobile industry shifts to electric automobiles (EVs) and hybrid vehicles The demand for diecast parts will likely to increase. They require components that are lightweight and durable, which makes diecast aluminum alloys and magnesium alloys more important. Malaysia’s emphasis on high-quality and innovation ensures it is able to meet the demands of an ever-changing automobile market.

In addition to the auto business, the Malaysian diecasting industry has seen significant increase due to the growth of telecommunications and electronic sectors. Diecasting of top-quality components is crucial in these areas, since parts have to conform to stringent technical specifications, and operate in harsh circumstances. Malaysian producers have taken on the task of making diecast parts like housings for computers, smartphones and various electronic devices. The accuracy and effectiveness of the diecasting process makes it the ideal choice for manufacturing these parts at a high-volume with the same level of high-end quality and long-lasting durability which international markets require.

One factor which sets Malaysia different from other countries within the industry of diecasting is the highly skilled workers. In the past the nation has invested large amounts in vocational and technical education to ensure that its workers are able to work with the latest manufacturing techniques. The commitment to developing skills allows Malaysian producers to work with advanced machinery, and to produce high-quality precision components that are in line with the highest standards in the world. Furthermore, the affordable labor cost, coupled with its expertise in technical aspects is a great cost-effective alternative for businesses seeking casting services. The mix of cost-effectiveness and experience has been the main reason behind the development of this industry.

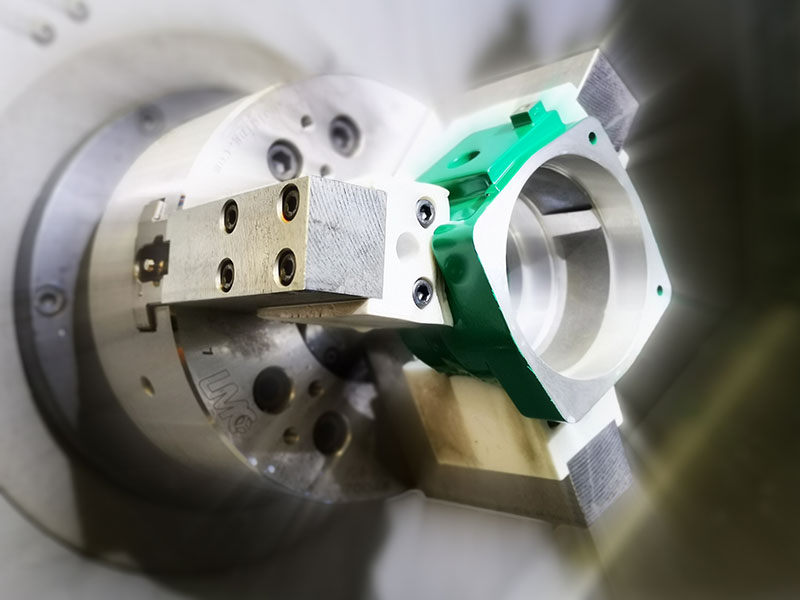

Innovation in technology is another key factor in the development of Zinc plating Malaysia. Industry has adopted the automation of computer-aided design (CAD) as well as robotics in order to improve production and boost the efficiency. The advancements in technology have helped manufacturers reduce their time to produce but also allow them to make greater complexity and customized components. In addition, developments in the field of materials research, including the utilization of lightweight alloys such as magnesium, allow Malaysian diecasting companies to provide creative solutions to fulfill the requirements of a variety of industries. Technology advancements are positioning Malaysia as an innovative center for diecasting that is adept at adapting to the ever-changing needs of the global market.

The future of the diecasting industry in Malaysia looks promising. In a world where industries like electronic, automotive and aerospace are increasingly demanding strong, lightweight material, Malaysia is well-positioned to satisfy this need. Malaysia’s commitment to sustainable techniques, like energy-efficient equipment and recycled materials, also increases its appeal to eco-friendly manufacturing companies. In addition, the focus of Malaysia on advancing its staff’s technological abilities and adopting cutting-edge technology will help ensure it stays in the forefront of global competition. With global clients looking for affordable and ad-hoc solutions to diecasting Malaysia’s position within the international diecasting market will likely to grow more in the next few time.

Diecasting, in the end, has been a key element of the manufacturing industry in Malaysia which has contributed significantly to the nation’s economic development as well as its industrial growth. Combining skilled labour along with advanced technology and strategic investments in the field of innovation allows Malaysia to become an industry leader on the diecasting industry. With the development of industries and demand for light and durable parts increases, Malaysia is poised to remain a major participant in the worldwide diecasting sector, offering quality, reliable and affordable solutions to customers across the globe.